which of the following is a type of machine safeguarding osha 10

A safety device may perform one of several functions. Machine Guarding Best Practices Occupational Health Safety Commonly Used Machine Guards 12 Table 2.

Machine Guarding Best Practices Occupational Health Safety

Machine safeguarding helps protect workers from preventable injuries in all three areas.

. Understanding the different types of mechanical motions is the first step towards protecting your workers from potential harm from the danger zones caused by them. The following are all machine safeguarding requirements except. One of the major goals of OSHA is to guard all machinery and equipment to eliminate hazards created by points of operation ingoing nip points rotating points and flying chips and sparks.

Any machine part function or process that may cause injury must be safeguarded. The most common types of machine guards are. Types of Machine Safeguards Gate devices.

Must prevent workers from lubricating a machine without removing the safeguard. 29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards including those created by point of operation in-running nip points rotating parts flying chips and sparks. To the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding.

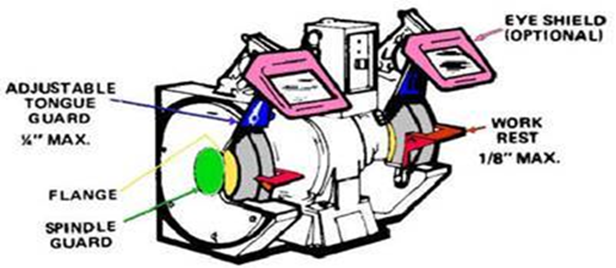

Primary Safeguarding Methods Two primary methods are used to safeguard machines. Collars couplings cams clutches flywheels shaft ends spindles and horizontal or vertical shafting are some examples of common rotating mechanisms which may be hazardous. Movable guard - a guard connected by mechanical means eg hinges or slides to the machine frame or an adjacent fixed element.

Point of Operation is the point where work is performed on the material EXCEPT. Barriers and guards that prevent contact. Eight Basic Types of Hazardous Mechanical Motions and Actions.

Criteria for Machine Safeguarding. Calculating Safe Mounting Distances For Safeguards Ehs Today. Which of the following is an example of a safeguarding device.

There seem to be as many hazards created by moving machine parts as there are types of machines. Guards and some types of. 3 Fixed adjustable access guard.

We can group machine safeguards under five general classifications. Rotating Motion In-Running Nip Point Reciprocating Motion Transverse Motion Cutting Action Punching Action Shearing Action. Which of the following is a type of machine safeguarding osha 10 Thursday May 19 2022 Any machine part function or process that may cause injury must be safeguarded.

Prevent contact keeping the workers hands arms or any other part safe from the moving part. Simply so what are the most common types of machine guarding. Machine safeguarding helps protect workers from preventable injuries in all three areas.

The words shall be guarded apply to most machines and equipment the University uses. Punching Actions Punching actions result when power is applied to a slide ram for the purpose of blanking drawing or stamping metal or other materials. This guard is usually preferable to all other types because of its relative simplicity and permanence.

Some machines require specific guarding methods and all machines. Commonly Used Machine Guards 12 Table 2. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area.

Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. Which of the following is NOT one of the four types of machine guards.

There are four general types of guards and well discuss them in the next section. The following are all machine safeguarding requirements except. Through the Alliance between OSHAs 10 Regional Offices and the Elevator Contractors of America ECA Elevator Industry Work Preservation Fund.

This OSH Answers fact sheet is based. Require the operator to use both hands on machine controls thus keeping both hands and body out of danger or provide a. Basics of Machine Safeguarding.

A Fixed b Adjustable c Interlocked d Flexible. _____ True or False. 1 Assigns responsibilities to those affected and outlines evacuation routes.

Due to this fact OSHA Occupational Safety Health Administration has established a set of standards around machine guarding. Hazardous Mechanical Motions and Actions. It does not specify all machine guarding requirements or all types of machinery or equipment.

The safeguarding system must have the following features. There is added danger when bolts nicks abrasions and projecting keys or set screws are exposed on rotating parts on machinery as shown in figure 2. Safeguards are essential for protecting workers from needless and preventable injuries.

This problem has been. All machines consist of three fundamental areas the point of. One basic form of machine guarding is called guarding by location According to OSHA this involves positioning or designing a machine so that the hazardous parts are away from areas where employees work or walk or alternatively installing enclosure walls or fences that restrict access to machines.

According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks The following are some key OSHA requirements for machine guarding according to. Which of the following is a type of machine safeguarding osha 10 Sunday May 8 2022 If a new guard causes interference 4. Safety trip control d.

The following are all machine safeguarding requirements except. Device that uses cable attached to hands which allows access to the point of operation when the slideram is up and automatically withdraws hands when the slideram begins to descend. A well-designed safeguarding system makes sure that the moving part is unreachable.

A good rule to. Types of Safeguarding Devices 13. Safeguards are essential for protecting workers from these preventable injuries.

A Fixed b Flexible c Interlocked d Adjustable. Feeding and ejection methods is a type of machine safeguarding. OSHA has set out a few general requirements that a safeguard must meet in order to ensure maximum protection.

What are the 2 types of primary safeguarding methods. Various types of machine guards available for machine guarding. Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Feeding and ejection methods is a type of machine safeguarding.

Interlocked guard - a guard attached and monitored by the control system in such a manner that it prevents the operation of hazardous machine functions under specified conditions. Guards are barriers which prevent access to danger areas. Examples of mechanisms involving cutting hazards include band saws circular saws boring or drilling machines turning machines lathes or milling machines.

What Is Machine Safeguarding T P Supply Co

Calculating Safe Mounting Distances For Safeguards Ehs Today

Osha Standards For Industrial Companies Industrial Safety Osha Safety Training Health And Safety Poster

Machine Guarding Named On Osha S Top 10 Violations In 2019 Quality Assurance Food Safety

Machine Guarding Safety Instructions Youtube

Machine Guarding Approach Management Services

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

Kpa Osha Machine Guard Requirement Compliance Checklist

How To Use Machine Guarding Youtube

What Is Machine Guarding And Why Is It Important Safetycompany Com

Crane Balancing Act Truck Cranes Crane Construction

2021 Top 10 Osha Violations Machine Guarding 2022 01 25 Ishn

Lockout Tagout And Machine Guarding 2015 04 01 Ishn

Machine Guarding Training Osha Standards Vubiz